For these type of Dynodrives, Cooling is done through Ventillation provided on the Frame. While the drive is running, air will circulate in between the drum and multipole Inductor, there by cooling the drive.

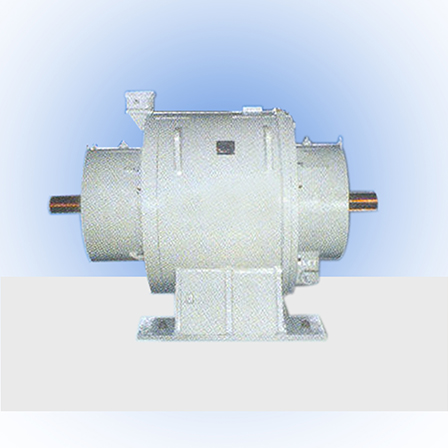

These are also Toatally Enclosed type Dynodrives.Coolong is achieved by Aluminium fins fitted on the Frame.

Dynodrive consists of Eddy Current Clutch coupled to a prime mover (usually a 3 phase Squirrel cage Induction Motor).There is no direct coupling between the Motor Shaft and the O/P Shaft. Torque is transferred from I/P shaft to O/P shaft by magnetic coupling. Eddy Current clutch consists of a ferromagnetic drum coupled to the prime mover and a multipole inductor made from special alloy steel rotates freely within the drum which is coupled to the load and an excitation coil.Variable

Excitation Voltage ranging from 0 to 80 VDC is given to Exc. Coil though a Thyristor Controlled Electronic Regulator. Depending upon the Exc.Voltage , O/P Shaft rpm varies from 0 to 1200 rpm (For 1500 rpm Prime mover).Max. Speed obtained at the O/P of Dynodrive will be 80% of the speed of the prime mover. Min Speed will be 10 % of the Max speed obtained at O/P shaft. Ie, if the prime mover rpm is 1500, max speed at the O/P will be 1200 rpm (80% of prime mover speed) and min speed will be 120 rpm(10 % of 1200). Dynodrive O/P will deliver Standard Torque of the Prime mover at any rpm ranging for 120 to 1200 rpm.

All eddy current variable speed drives have an integral tacho-generator mounted around the output shaft, to give voltage and frequency proportional to speed, which is used for speed reference feed back signal to the controller and maintains the output speed within 2% for the load changes from 90% to 10%. It can also be used for speed indication. We are manufacturing 3 Types of Dynodrives ranging from 0.4 KW up to 300 KW.